Our Services

- Conception of products and production processes

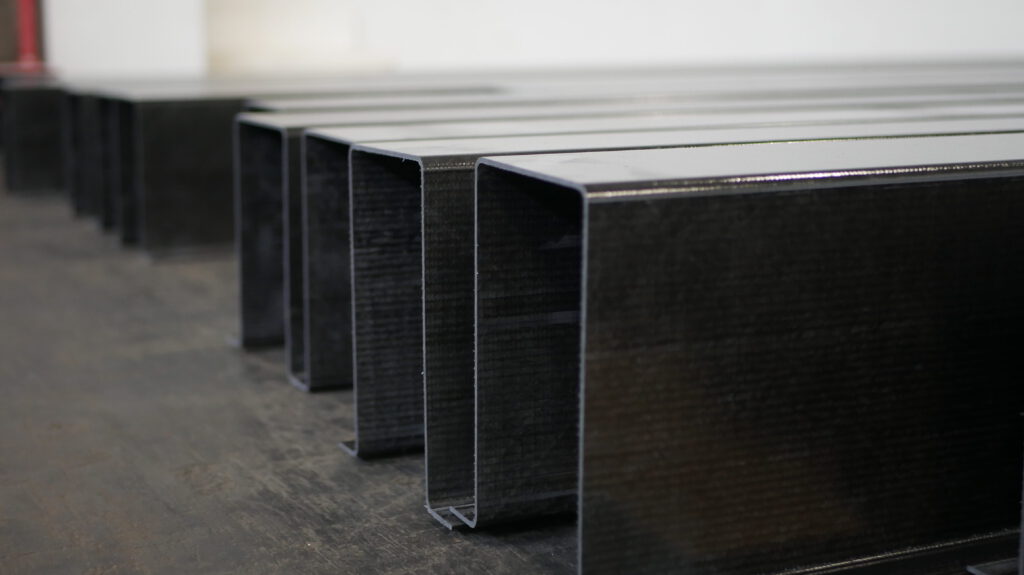

- Series production and mechanical processing of multiaxial-reinforced profiles

- Series assembly and joining of components and modules

- Production of prototypes and small series (pultrusion and vacuum infusion)

- Quality checks during production, production of coupons and production of material cards

Exemplary production developments:

Mercedes-Benz Sprinter

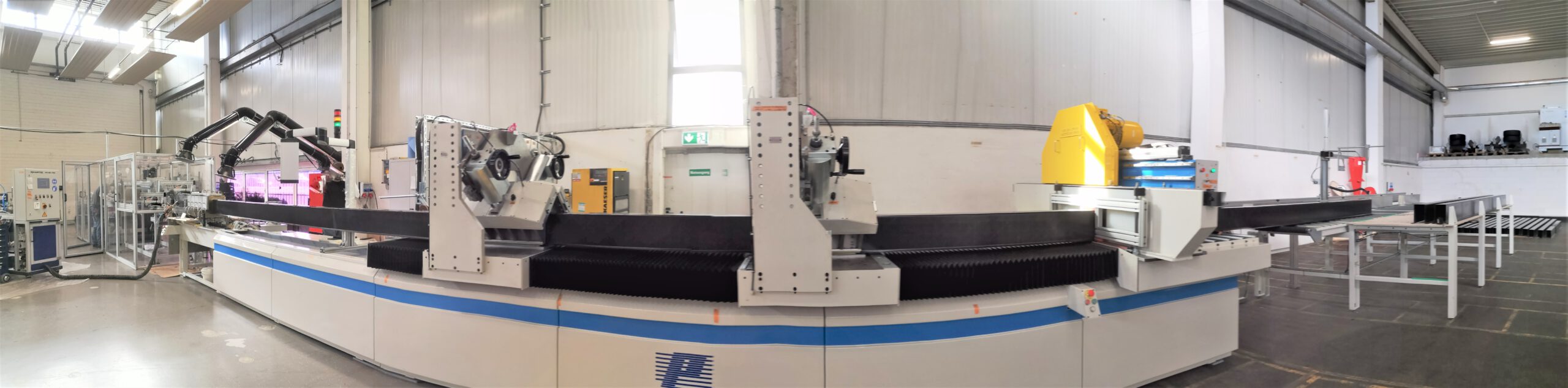

Skills and equipment

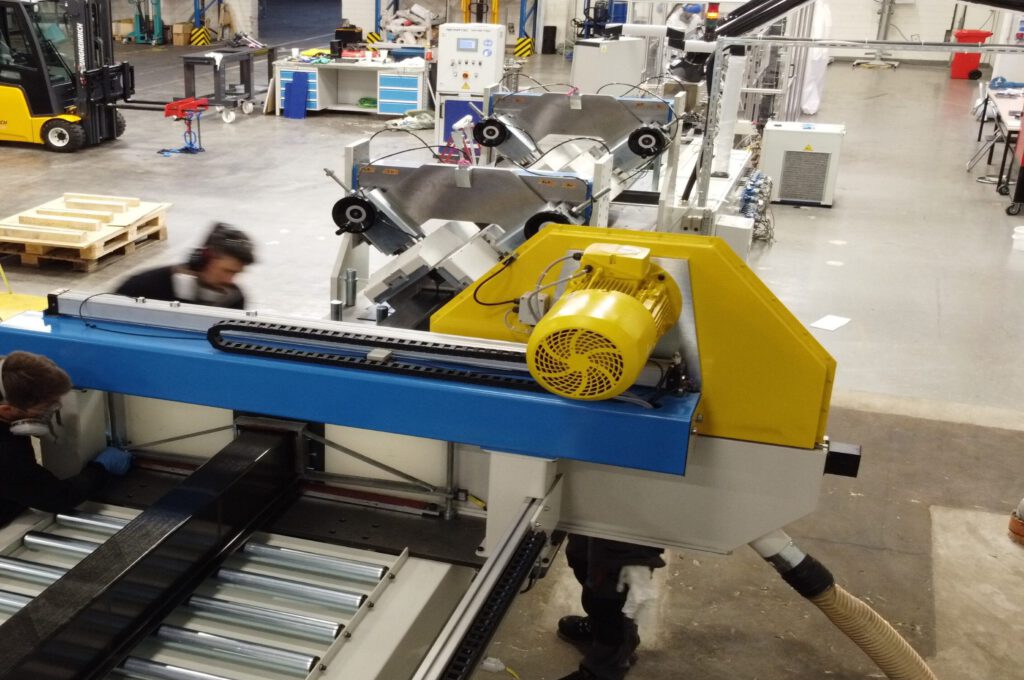

- 20t pultrusion system (pulling force measurement, 18 heating elements (up to 250°C), cooling system (injection box), data recording of relevant process parameters, sawing unit and automatic component removal after length cutting)

- Dosing system with agitator for processing highly reactive resin systems and additives

- System supplier with internal component and module assembly

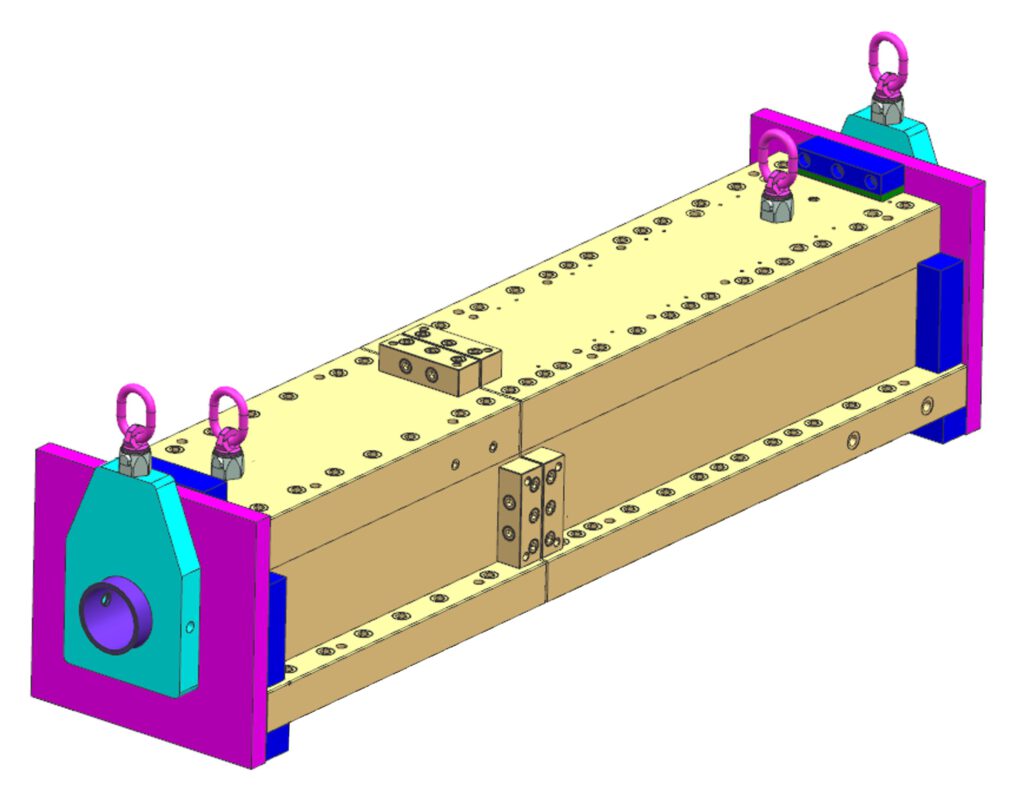

- Individual mounting racks for reliable joining of the components

Development services

- Development of pultrusion and assembly processes

- Design, optimization and series maturation of pultrusion processes:

- Creation of specifications for pultrusion systems

- Retrofitting/optimization of existing pultrusion systems

- Consulting: Component Design

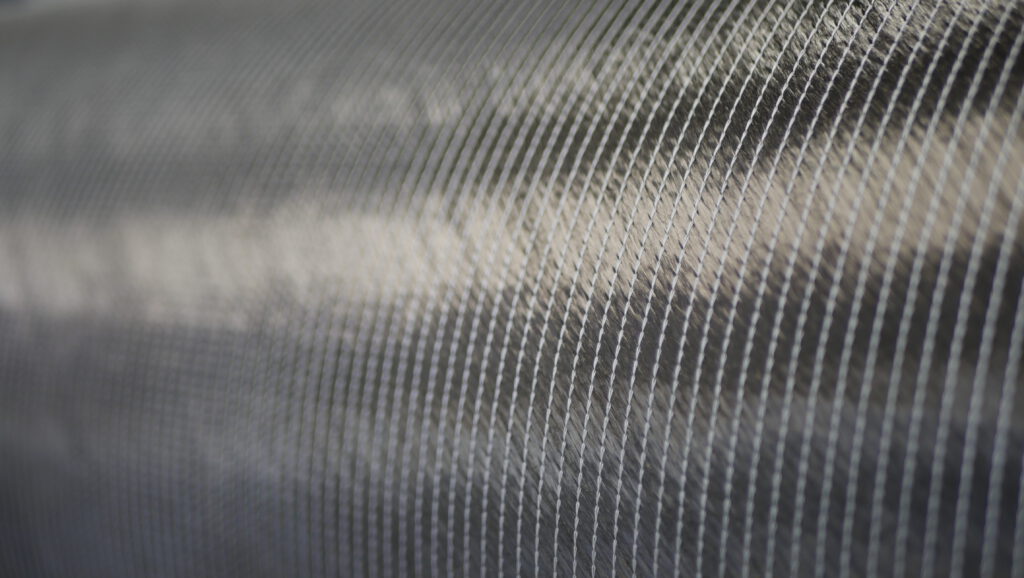

- Consulting: Material selection (textile semi-finished products & matrix)

- Cost estimation of profiles / production lines

- Validation of resin systems for pultrusion processes

- Investigation of the behaviour of multiaxial objects, UD/rovings, excipients, nonwovens and hybrid structures in the pultrusion process

- Development of series concepts for individual production scenarios

Do you have a possible project or a question about development services?

We would be pleased if you contact us:

or

+49 4141 788 55 00